Our Capabilities

Our full-service facility is one-of-a-kind. With more than 100,000 square feet of space, we can scale accordingly with you from the moment you conceptualize your product, through development and commercialization.

That means we stay on top of trends, help with your new product development, optimize your existing product, get you the labels you need (Yes, we help with Organic, Non-GMO, Gluten-Free, Vegan—you name it!), scale up, and even help commercialize your product.

Plus, our quality standards, audit capabilities, and level 3 SQF rating are some of the industry’s highest.

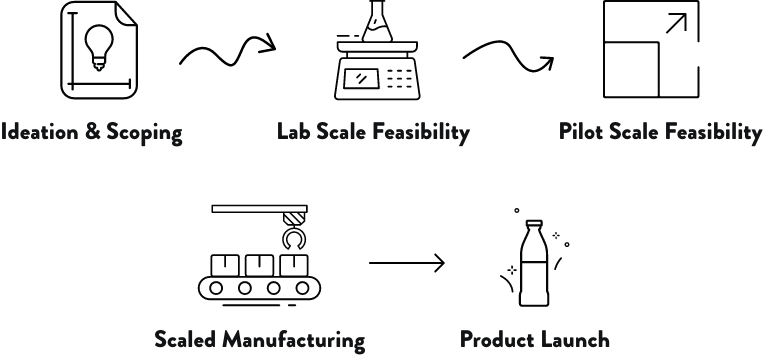

Our Process

Here’s what a partnership with Flavor Insights might look like for you:

We’re determined to navigate your complex ingredient challenges while ensuring robust product development practices along the way! We pride ourselves on being a catalyst for innovation—let’s collaborate to overcome current & future barriers to differentiation.

We’ve learned concept to commercialization is never a linear process.

We provide development insights by translating the abstract and general to the concrete and specific.

Flavor Delivery

Delivering the best flavor into a finished product requires many technical considerations. From solubility, liquid or dry needs, solvent requirements, shelf-life and stability, matrix interactions, and more—the method of delivery is vital to your product’s taste. We’ll walk you through all the options, from spray dry, liquid, powdered, and plated flavor delivery.

Spray-Dried Flavors

With one of the largest spray dryers on the West Coast, we can create mouth-watering flavors for you. Creating spray-dried flavors is one of our specialties.

For developers seeking a high-impact, longer shelf-life flavor, dried formats are often the best option. Using spray dry encapsulations, concentrated flavors can be sealed away from the outside environment, significantly increasing the flavor profile’s stability and impact. Spray-dried flavors also have a low moisture level which can provide various product matrix benefits, including clean label options. High flavor loading through encapsulation helps to deliver both impact and cost-effectiveness.

In short, our chemists put flavor emulsions into our spray dryer, creating a long, wonderful shelf-life via encapsulated flavor. From lab to pilot to full-scale—we have an efficient process that will meet your needs.

Liquid Flavors

Searching for a partner to create the perfect liquid flavor for your application? We can help. Our facility can help you create high-impact taste profiles for customized solubility conditions, including flavor systems that are:

• Water-soluble

• Oil-soluble

• Alcohol extracts

• Fruit flavors

• UHT (ultra-high temperature) stable flavors

• TTB-approved flavors are also available

Powdered Flavors

The mouthfeel of spray-dried and ribbon blended powder flavors is second to none. Flavor strength, flowability, and moisture are all central to our unique dual blending process. As a powdered flavorings manufacturer with experience building a brand in the sports nutrition market, you can count on quality for every flavor outcome.

Plated Flavors

If you’re looking for cost advantages, ease of processing, and aroma release benefits, our plated flavor technologies may be a good fit. Plating is a technique where a liquid flavor is added to a tank filled with a powdered carrier and mixed until the carrier is completely coated in flavor.

Ready To Get Started?

When it comes to developing your product, whatever your market category, your hustle is our hustle. We have application expertise that wins in beverage, protein, performance and sports nutrition, supplements, beauty, bars, and alcohol and craft beverage markets.